Enhancing Safety and Performance with High-Visibility Line Markings Using Aerosol Machines

High-visibility line markings are vital for road safety and efficient traffic management, guiding vehicles and pedestrians while preventing accidents. Aerosol line marking machines have transformed this process by offering superior precision, consistency, and ease of use. Designed for various applications, from highways and parking lots to sports fields, these machines ensure durable, uniform markings with minimal effort. Their adjustable settings, fast application, and compatibility with eco-friendly paints make them both efficient and sustainable. This blog explores how aerosol line marking machines enhance safety, improve performance, and support environmentally responsible practices through innovative design and advanced application technology.

Key Takeaways

- High-visibility line markings are essential for road safety, effectively managing traffic and preventing accidents by guiding vehicles and pedestrians.

- Aerosol line marking machines enhance efficiency and precision, offering adjustable line widths and various models to cater to different marking needs.

- Regular maintenance and the use of eco-friendly, low-VOC paints are crucial for the longevity of aerosol marking machines and minimizing environmental impact.

The Importance of High-Visibility Line Markings

High-visibility line markings are not just lines on the road; they are lifelines that ensure safety and order on our roadways. These markings play a crucial role in managing traffic, guiding vehicles, and preventing accidents. Imagine driving on a busy highway without clear lane markings or navigating a parking lot without visible lines. The chaos and confusion that would ensue highlight the importance of these markings in our daily lives.

These markings help in identifying lanes, crosswalks, and designated pathways, enhancing the safety of both drivers and pedestrians. For instance, clearly marked pedestrian crossings significantly reduce the risk of accidents, ensuring that pedestrians can cross roads safely. Similarly, visible stop lines and lane dividers help drivers make informed decisions, reducing the likelihood of collisions and improving overall traffic flow.

Moreover, high-visibility markings contribute to the efficiency and effectiveness of traffic management by ensuring compliance with regulations. They provide clear instructions to drivers, helping them navigate complex intersections and busy streets with ease. This not only enhances road safety but also reduces heavy traffic, making our roads more efficient and less stressful to navigate.

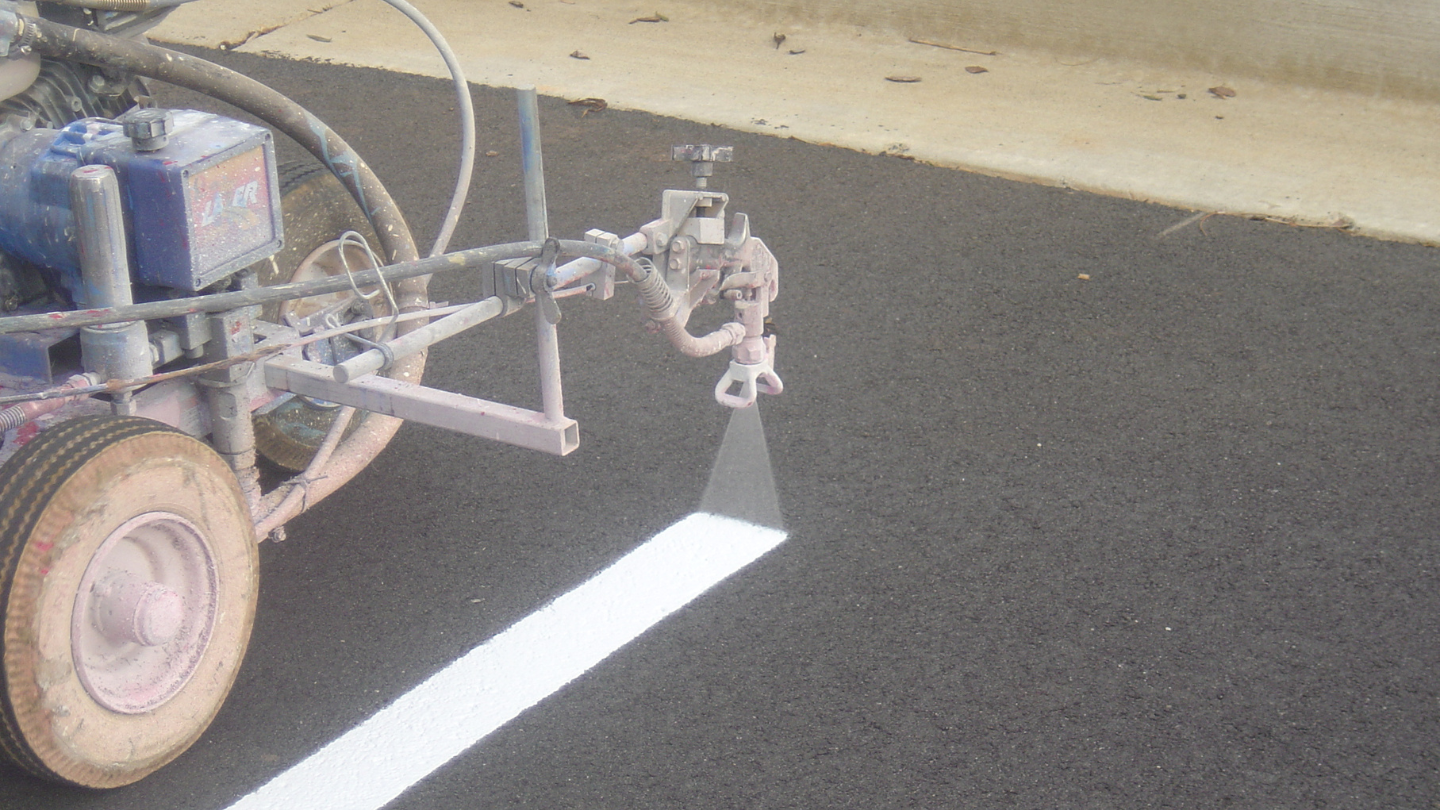

Aerosol line marking machines are versatile and can be utilized on diverse surfaces such as athletic fields, parking lots, and road surfaces. Whether it’s marking lines on a busy highway or outlining the boundaries of a sports field, these machines ensure that the markings are clear, precise, and long-lasting. This versatility makes them an essential tool for various marking projects, ensuring that every surface is marked with the highest level of accuracy and visibility. Many professionals now rely on striping machines to achieve this level of performance across different applications.

Understanding Aerosol Machines for Line Marking

Aerosol machines have revolutionized the process of line marking, offering a level of precision and efficiency that traditional methods simply can’t match. These machines use aerosol cans, nozzles, or spray guns to apply paint, guaranteeing consistent coverage and precise application. The result is straight, uniform lines essential for road safety and traffic management.

The function of a line marking machine is to apply paint or thermoplastic material to create straight, consistent lines. Professional-grade aerosol paint machines offer enhanced accuracy, faster application, and consistent performance. These machines are designed to improve efficiency and reduce paint waste, making them an ideal choice for large-scale marking projects.

Several types of aerosol field marking machines exist. These include walk-behind, ride-on, and handheld models. Each type offers unique benefits, allowing users to choose the best machine for their specific needs. Whether it’s a small touch-up job or a major road marking project, there’s an aerosol machine designed to deliver clear and visible markings with ease, including various road marking machines and field marking equipment options. For sports applications, athletic field marking machines are particularly effective in ensuring precision and uniformity.

For professionals comparing different types, the comprehensive buyer’s guide to aerosol field marking machines provides valuable insights on how to select the right model for your project’s scope and surface type.

Key Features of Aerosol Line Marking Machines

Aerosol line marking machines come equipped with several key features that enhance their performance and usability. These features include larger paint reservoirs for extended operation, user-friendly controls to minimize operator fatigue, and adjustable line widths for precise marking, including high-pressure airless systems.

Each of these features plays a vital role in ensuring that the long-lasting markings are clear, durable, and fit for their intended purpose. The features to look for in an aerosol paint machine are essential to consider before purchase, as they directly influence performance and ease of use.

Paint Capacity

One of the most critical aspects of an aerosol line marking machine is its paint capacity. Larger paint reservoirs allow for extended operation without frequent interruptions, significantly reducing the need for refilling. This not only increases operational efficiency but also enhances productivity by allowing operators to focus on marking lines rather than constantly stopping to refill the machine.

Modern electric striping machines often feature higher-capacity tanks, ensuring continuous operation for large-scale marking projects. The overall impact is higher productivity in marking projects, as operators can work more efficiently and complete tasks faster.

Ease of Use

Ease of use is another crucial feature of aerosol line marking machines. Key aspects include:

- User-friendly controls

- Ergonomic design that enhances productivity and minimizes operator fatigue

- Features that allow for easy modifications of settings, making the machine accessible for operators of all skill levels.

This ease of use reduces operator fatigue, enabling longer work periods with precision and ensuring that markings are applied accurately and efficiently.

Adjustable Line Width

The flexibility of customizable line widths in aerosol machines is a game-changer for various marking tasks. This feature allows operators to adapt the machine for different surfaces and purposes, ensuring that the markings are both functional and aesthetically pleasing. Whether it’s creating thin stop lines or broader lane dividers, adjustable line width ensures that the markings are precise and fit for their intended purpose.

For maintenance and optimal performance, using a paint machine cleaner regularly helps prevent paint buildup and ensures smooth operation.

Types of Aerosol Line Marking Machines

Aerosol line marking machines come in various types, each designed to cater to different needs and applications. From handheld models used for small touch-ups to walk-behind machines ideal for medium to large projects, these machines are versatile and adaptable to various surface types.

Understanding the different types of aerosol line marking machines allows users to choose the best tool for their specific marking projects. For those looking for a detailed comparison between machine categories, the ultimate guide to robotic field marking paints vs aerosol field marking offers a valuable perspective on efficiency and precision.

Handheld Aerosol Line Marking Machines

Handheld aerosol marking machines are designed for small projects and touch-ups. These lightweight and portable handheld machines allow for easy transport and quick deployment across various job sites. Their user-friendly design makes them suitable for quick applications, enhancing productivity and efficiency.

Overall, handheld aerosol marking machines provide an effective solution for maintaining high-visibility lines in various settings.

Walk-Behind Aerosol Line Marking Machines

Walk-behind aerosol marking machines are recommended for medium to large projects. These machines provide additional control capabilities for larger markings, ensuring precision and consistency.

Self-propelled walk-behind machines enhance operator comfort by minimizing fatigue during extended use, thanks to their ergonomic design. They are designed to handle various surface types, making them versatile and efficient for a wide range of marking projects.

Enhancing Safety with High-Visibility Markings

High-visibility line markings enhance safety by providing clear guidance and reducing the likelihood of accidents. Properly maintained road markings are essential for effective traffic management, guiding drivers and helping prevent collisions. For instance, high-visibility crosswalks can lead to a significant decrease in pedestrian injury crashes by up to 40%. Similarly, the use of advanced yield or stop markings and signs can reduce pedestrian crashes by approximately 25%.

The maintenance checklist for aerosol field marking machines emphasizes that consistent upkeep of your marking equipment ensures visibility and safety over time, preventing premature wear or fading.

The color and pattern of road markings are vital for communication with drivers, aiding in timely decision-making. Bright, contrasting colors and clearly defined patterns ensure that drivers can easily interpret the markings, whether it’s a stop line, a pedestrian crossing, or a lane divider. Retroreflective markings enhance visibility during nighttime driving, further improving road safety.

In parking lots and other areas with heavy pedestrian traffic, clear and visible markings are crucial for preventing accidents and ensuring smooth traffic flow. These markings help designate parking spaces, guide traffic, and highlight pedestrian pathways, making the area safer for everyone. Whether it’s a busy road or a quiet parking lot, high-visibility line markings play a crucial role in maintaining safety and order.

Marking athletic fields is another area where high-visibility line markings are essential. Clear and precise markings ensure that players can easily see the boundaries and lines, enhancing the overall experience and safety of the game. Whether it’s for American football, baseball, or any other sport, high-visibility markings are crucial for both players and spectators. Professionals in this area often rely on athletic field marking machines for consistent and durable results.

Performance Evaluation and Efficiency

Evaluating the performance and efficiency of aerosol marking machines is crucial for ensuring that they meet the demands of various marking projects. These machines significantly reduce the time required for line marking compared to traditional methods, thanks to their advanced technology and precise application capabilities.

Key factors to consider include spray tips and accessories, as well as speed and productivity.

Spray Tips and Accessories

Spray tips and accessories play a vital role in the performance of aerosol marking machines. Different spray tips can alter the pattern and thickness of spray paint applied, ensuring optimal marking quality for various surfaces. The spray width can be freely adjusted, allowing for precise markings on a wide range of surfaces using a spray gun.

Additionally, power and capacity significantly influence the performance of the machine, affecting flow rates, speed, and overall marking quality.

Speed and Productivity

Speed plays a vital role in the efficient completion of larger projects. It is an essential factor to consider. Enhanced speed reduces traffic interruptions and other activities in the area, making the marking process smoother and more efficient. Dual-color line stripers allow for quicker job completion, while self-propelled line stripers can double productivity and reduce operator fatigue.

These features ensure high efficiency and reliable performance, making aerosol marking machines an ideal choice for large-scale marking projects.

Maintenance and Longevity

Regular maintenance is essential for the longevity and operational efficiency of aerosol marking machines. Routine upkeep ensures that these machines remain reliable and perform at their best over time.

Routine Maintenance

Adhering to maintenance guidelines preserves functionality, enhances efficiency, and reduces breakdown risks. Regular maintenance:

- Extends the lifespan of aerosol machines

- Ensures consistent paint flow

- Requires routine inspection and cleaning to prevent paint buildup and maintain functionality

Crucial practices for routine maintenance include regular cleaning, filter checks, and professional servicing. Proper storage and handling also maintain the essential tools and the equipment’s condition, ensuring it is always ready for use.

Durable Construction

Durable construction is essential for the longevity of aerosol marking machines. Robust construction ensures resilience against wear and tear, providing long-lasting performance. Durability features maximize investment and ensure equipment remains in top condition, reducing the need for frequent replacements and repairs.

This focus on durability ensures that the machines can withstand the demands of large-scale projects and deliver precise applications consistently.

Environmental Considerations

Environmental considerations are crucial when selecting and using aerosol marking machines. Hydrocarbon propellants used in these machines have a low global warming potential and minimal environmental impact.

US Specialty Coatings emphasizes the highest standards in performance and environmental responsibility across its product range, focusing on sustainability and customer trust. This commitment ensures that their products help achieve vibrant and precise markings while minimizing environmental impact.

Low VOC Paints

Low VOC (Volatile Organic Compounds) paints are designed to emit fewer harmful compounds, reducing the environmental impact of field marking activities. Most modern aerosol field marking machines are compatible with low VOC paints, which support longer shelf life for products due to reduced chemical degradation.

Using low VOC paints extends the operational season for marking projects, particularly in colder weather, achieving high-quality results while applying paint and minimizing the environmental footprint.

Eco-Friendly Practices

Implementing eco-friendly practices in aerosol field marking is vital for minimizing environmental impact. Using low VOC paints is a recommended practice that contributes to safer and more sustainable marking results. These practices reduce harmful emissions and improve air quality, ensuring that marking projects are conducted responsibly and sustainably.

Proper disposal of materials and adherence to environmental guidelines further support these efforts.

Making an Informed Purchase

When choosing a line marking machine, consider the size and scope of your intended projects to ensure appropriate machine capacity. Key factors to consider include:

- Project size

- Surface type

- Marking material

- Precision

- Efficiency

- Durability

- Ease of use

- Maintenance requirements

Understanding these factors helps in selecting a machine that meets your specific needs and delivers optimal performance.

Key features to consider include adjustable line width, efficient material delivery systems, and the type of spray mechanisms. Advanced features such as smart systems and GPS technology, along with cutting-edge technology, can enhance the accuracy and efficiency of marking projects. These features ensure that the machine can handle complex marking tasks with precision, making it a valuable addition to any automated systems marking project that utilizes line marking technology.

Investing in a reputable brand for line marking machines can save costs in the long run due to durability and reliability. Using high-quality marking equipment enhances service offerings. This professionalism in results helps to attract more clients. By choosing a trusted brand, you ensure that the machine will perform consistently and deliver long-lasting lines with excellent line quality, enhancing your reputation and the overall success of your projects.

Users should understand the various models and their specific features to make strategic investments in aerosol machines. Researching and comparing different models allows you to choose the best machine for your needs, ensuring that you get the most value for your investment and achieve excellent results in your marketing projects.

Final Thoughts

High-visibility line markings play a crucial role in improving road safety, traffic management, and overall navigation efficiency. Throughout this blog, we explored how aerosol line marking machines deliver precise, durable, and long-lasting results across various applications, from highways and parking lots to athletic fields. Their advanced features, such as adjustable line widths, ergonomic designs, and eco-friendly capabilities, make them an indispensable tool for achieving consistency, visibility, and safety in every marking project.

US SPECIALTY COATINGS continues to lead the industry with innovation and quality, offering a wide range of high-performance solutions, including the reliable aerosol paint machine. Designed for superior accuracy and durability, their products help professionals complete marking projects efficiently while maintaining the highest standards of safety and sustainability. Our dedication to craftsmanship and technological advancement makes us a trusted partner for all your line marking needs.

Frequently Asked Questions

Why are high-visibility line markings important?

High-visibility line markings are crucial for enhancing road safety by effectively managing traffic and guiding vehicles. Their clear visibility significantly contributes to a safer driving environment.

How do aerosol line marking machines enhance performance?

Aerosol line marking machines significantly enhance performance by offering improved accuracy, speed of application, and consistent results, making them well-suited for diverse marking projects.

What features should I consider when choosing a line marking machine?

When choosing a line marking machine, it is essential to consider features such as adjustable line width, efficient material delivery systems, and the type of spray mechanisms. Additionally, advanced options like smart systems and GPS technology can significantly improve both accuracy and efficiency.

How can I ensure the longevity and efficiency of my aerosol marking machine?

To ensure the longevity and efficiency of your aerosol marking machine, prioritize regular maintenance through routine inspection, cleaning, and professional servicing. This proactive approach is crucial in preserving functionality and extending the machine’s lifespan.