Bulk Striping Machines for Large Facilities: Maximizing Efficiency

Large facilities such as parking lots, sports complexes, and industrial campuses require precise, high-volume line marking to maintain safety and organization. Relying on manual striping methods is time-consuming, labour-intensive, and prone to inconsistencies. Bulk striping machines streamline this process, delivering superior efficiency, consistent line quality, and significant cost savings. This blog explores how these machines work, key features to consider, top-performing models, and essential maintenance practices to help facility managers and contractors maximize performance and profitability.

Key Takeaways

- Bulk striping machines enhance efficiency and precision for large-scale striping projects, leading to cost savings and improved customer satisfaction.

- Key features such as high-capacity paint tanks and adjustable spray tips are crucial for maximizing machine performance and versatility.

- Regular maintenance, including cleaning and seasonal adjustments, is essential for maintaining the longevity and efficiency of bulk striping machines.

Why Bulk Striping Machines are Essential for Large Facilities

When it comes to large-scale striping jobs, the efficiency and precision offered by bulk striping machines are unparalleled. Imagine the daunting task of manually marking an entire parking lot or athletic field. Not only would it be time-consuming, but the likelihood of inconsistent lines and errors would be high. Bulk parking lot striping machines streamline the process, enabling quicker completion of parking lot striping jobs with greater accuracy using a parking lot striping machine.

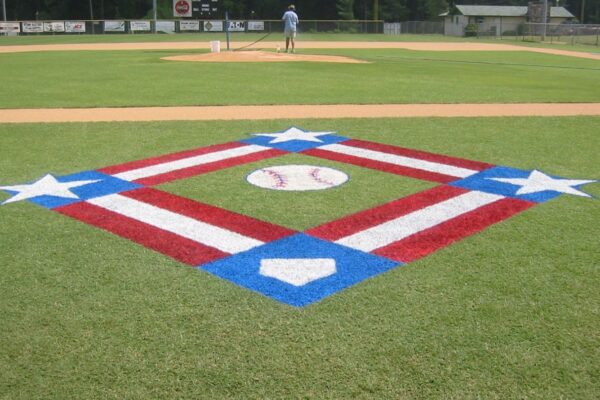

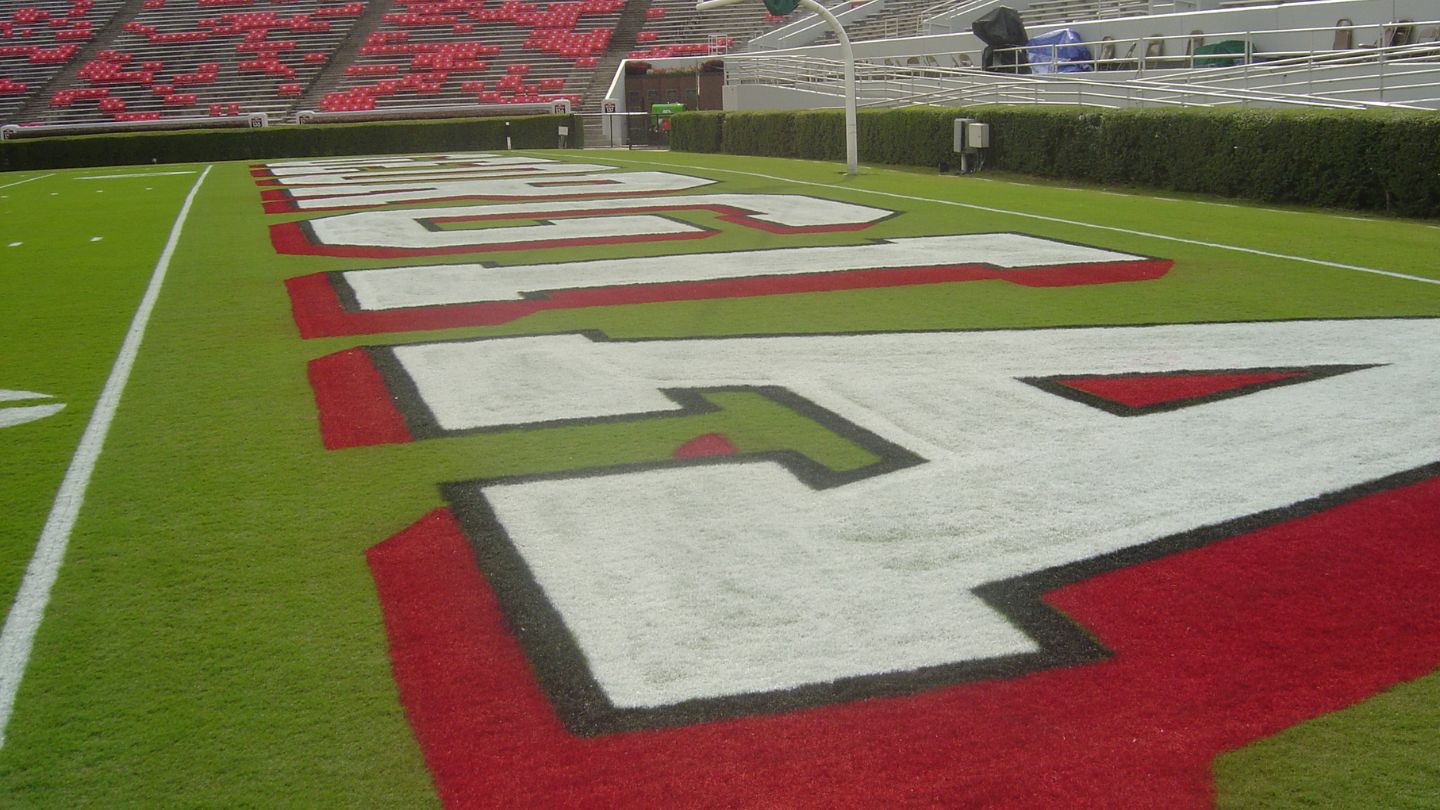

The quality of the striping work is another critical aspect. Consistent, high-quality, durable lines are essential, not just for aesthetics but also for safety and organization. Bulk striping machines ensure that each line is uniform and precise, which is crucial for maintaining a professional appearance and enhancing the functionality of the space. For instance, after asphalt maintenance, sharp and clear line markings can significantly improve the overall look of the property and promote safe traffic flow.

Moreover, investing in high-quality striping machines can lead to substantial long-term cost savings. These machines reduce costs, reduce labor costs, increase productivity, and eventually pay for themselves, opening doors to more business opportunities. Satisfied customers who see professional and consistent results are more likely to return and recommend your services, thereby boosting your line striping business.

Key Features to Look for in Bulk Striping Machines

Selecting the right striping machine for your facility is crucial to achieving optimal results. Applying expert tips on how to choose the right paint striping machine ensures the best match for surface type, paint capacity, and spray control, delivering efficiency and precise results. Bulk striping machines are designed to operate on diverse surfaces such as asphalt, concrete, and grass, making them versatile tools for various applications. When choosing a machine, consider features that enhance efficiency and reduce labor costs, ultimately contributing to long-term savings.

Key features to look for include high-capacity paint tanks, adjustable spray tips, and ergonomic designs. These elements not only improve the machine’s functionality but also ensure that your striping work is completed with precision and minimal downtime.

Let’s delve into these features in more detail.

High-Capacity Paint Tanks

High-capacity paint tanks are a game-changer for large-scale striping projects. They enable longer operational periods by reducing the need for frequent refills, which means less downtime and more continuous work. For example, models like the Titan PowrLiner 8955 come with a large hopper capacity, making them suitable for heavy-duty tasks and ensuring that you can cover more ground in less time.

A high-capacity tank is particularly beneficial for extensive projects such as striping parking lots and athletic fields. Whether you’re using water-based paint or oil-based paint, these tanks ensure that you have enough paint to complete your job without interruptions, leading to more efficient and effective project completion.

Adjustable Spray Tips

Adjustable spray tips are essential for achieving the precise line widths required for different striping jobs. These tips allow you to tailor the line thickness to meet specific project needs, whether it’s for parking spaces, sports fields, or other applications. This flexibility not only improves the quality of the paint striping work but also ensures that the markings are clear and consistent.

Having control over the spray tips means you can easily switch between different line widths, making the striping machine more versatile and suitable for a variety of tasks. This adaptability is crucial for maintaining high standards across all your line striping projects.

Ergonomic Designs

Ergonomic designs in striping machines can significantly enhance operator comfort and reduce fatigue, especially during lengthy operations. Features such as adjustable handles and cushioned grips help minimize strain, allowing operators to work more efficiently and for longer periods. This combination of comfort and productivity makes ergonomic designs a must-have for any striping machine.

Ergonomic striping machines reduce operator fatigue, which boosts enhanced productivity and overall performance. When operators are comfortable, they are more likely to produce consistent and high-quality results, which is essential for large-scale striping projects. Additionally, these machines can help enhance productivity.

Top Bulk Striping Machines for Large Facilities

- Walk-behind models

- Ride-on machines, which are ideal for large areas due to their ability to cover extensive ground quickly while minimizing operator fatigue

- A walk-behind striping machine

- Handheld models

Each type has its unique advantages.

Handheld striping machines offer versatility for detailed work and are particularly effective for quick touch-ups in confined spaces. They are perfect for smaller jobs or areas that require more precision. On the other hand, walk-behind striping machines are more portable and cost-effective solutions, making them suitable for small jobs to medium-sized projects. Handheld machines can also be utilized for various applications.

Ultimately, the right line striping machine for your needs will depend on the specific requirements of your projects. Whether it’s a large-scale striping job or a smaller, more detailed task, having the right equipment can make all the difference in achieving professional and consistent results.

Enhancing Efficiency with Advanced Striping Machine Accessories

Exploring top accessories like laser guides, reflective bead dispensers, and stencils can enhance the productivity and quality of your striping work on various surfaces.

Laser Guides

Laser guides are invaluable tools for achieving precise lines. They serve as visual references, projecting a line on the surface to help operators maintain straight lines and consistent lines. This added precision ensures that your striping work is professional and meets the highest standards.

Laser guides enhance the quality of the markings and make the striping process more efficient. Operators can quickly and easily align the machine, resulting in faster and more accurate striping jobs.

Reflective Bead Dispensers

Reflective bead dispensers are essential accessories for improving the visibility of line markings, especially in low-light conditions. By incorporating reflective beads into the striping paint, the markings become highly visible, enhancing safety for drivers and pedestrians. This is particularly important in areas such as parking lots and roadways where visibility is crucial.

Using reflective bead dispensers not only improves safety but also ensures that your striping work meets regulatory standards. Enhanced visibility from reflective beads promotes a safer environment and contributes to the overall quality of the project.

Stencils and Templates

Stencils and templates are vital for creating uniform markings that comply with specific regulatory requirements. Using stencils allows for consistent and precise markings, whether for parking spaces, directional arrows, or other markings of line marking. This uniformity is essential for maintaining a professional appearance and ensuring that the markings are easily understood by drivers and pedestrians.

Using 1/8” thick reusable plastic or aluminum for ADA stencils ensures durability and compliance with regulations. Having the right stencils and templates can make a significant difference in the quality and consistency of your striping work.

Maintenance Tips for Bulk Striping Machines

To keep your machines in top condition, it’s important to perform regular cleaning and seasonal adjustments. These maintenance tips will help you maintain the functionality and reliability of your striping equipment.

Regular Cleaning

Regular cleaning is a fundamental aspect of creating clean maintenance for your striping machines. After each use, it’s vital to clean and inspect the spray tips, hoses, and nozzles to avoid clogs and ensure smooth operation. This routine maintenance helps maintain the quality and consistency of the clean lines, which is essential for professional results.

For professional contractors and those in the asphalt maintenance business, regular cleaning can significantly improve the lifespan and performance of the machines. Keeping the equipment in top condition ensures your striping work is always of the highest quality.

Seasonal Adjustments

Seasonal adjustments are necessary to ensure that your striping machines perform optimally throughout the year. Changes in temperature and humidity can affect the paint’s application properties and drying times, making it crucial to adjust machine settings accordingly. Regular calibration of the equipment ensures precise paint application and maintains performance quality.

These adjustments contribute significantly to the longevity and efficiency of the machines. By adapting to varying weather conditions, you can ensure that your striping work remains consistent and professional all year round.

Where to Buy Reliable Bulk Striping Machines

Exploring additional trusted suppliers who provide quality striping equipment and accessories can also be beneficial. By partnering with reputable suppliers, you can ensure that you have the right tools and support to meet the needs of your line striping business.

Final Thoughts

Bulk striping machines are critical assets for managing large-scale projects such as parking lots, athletic fields, and industrial facilities. By combining speed, accuracy, and long-term cost savings, these machines outperform manual methods and ensure consistent, professional-quality line markings. Advanced features like high-capacity paint tanks, adjustable spray tips, and ergonomic designs, along with accessories such as laser guides, reflective bead dispensers, and stencils, further boost efficiency and precision for every job.

For superior results and reliable performance, US SPECIALTY COATINGS offers industry-leading striping machines built to handle demanding applications with ease. Our commitment to quality products, dependable support, and innovative technology makes us a trusted partner for contractors and facility managers seeking optimal productivity and flawless results.

Frequently Asked Questions

What are the main advantages of using bulk striping machines over manual methods?

Using bulk striping machines enhances speed and efficiency in line striping, ensuring consistent quality while lowering labor costs. This makes them a crucial investment for large facilities seeking reliable results.

What features should I look for when selecting a bulk striping machine?

When selecting a bulk striping machine, prioritize high-capacity paint tanks, adjustable spray tips for customizable line widths, and an ergonomic design to minimize operator fatigue. These features collectively enhance efficiency and productivity.

How can I enhance the efficiency of my striping machine?

To enhance the efficiency of your striping machine, consider incorporating advanced accessories like laser guides for precise alignment, reflective bead dispensers for better visibility, and stencils for consistent markings. These tools can greatly improve both the quality and productivity of your striping tasks.

What maintenance tips are essential for prolonging the life of my striping machine?

To prolong the life of your striping machine, it is essential to regularly clean spray tips, hoses, and nozzles after each use, and make seasonal adjustments for temperature and humidity changes. These maintenance practices will ensure your equipment performs optimally and lasts longer.